EPRI Insulator Leakage Current Monitor

EPRI offers two types of leakage current monitor; one for long rod, composite and substation post insulators, and another for glass or porcelain disc insulators. These robust, low-cost, patented RF Monitors measure leakage currents across insulators. We designed these self-contained units to wirelessly report measurement data and status via a radio frequency (RF) link to a base station which aggregates, stores, and transmits the data.

Our measurement approach

We designed our Leakage Current RF Monitors to have the following measurement features:

- The current is measured with a ferrous current transformer surrounding a straight current conductor as primary winding. This increases resiliency during flashover events and reduces impedance in the current path.

- The system is designed to monitor leakage current without interruption.

- The peak leakage current values over an adjustable period are binned and stored (default period is 60s).

- A secure, two-way communication protocol enables remote adjustment of measurement parameters.

- Onboard, automatic remote calibration of leakage current values obviates the need to uninstall units for this purpose.

- Two different sensitivities of leakage current monitors are available depending of type of insulator being monitored (e.g. glass/ porcelain vs. composite and RTV coated).

- The installed battery is designed to power the device for more than 10 years.

- Sensor health parameters are reported.

Algorithms and advanced analytics

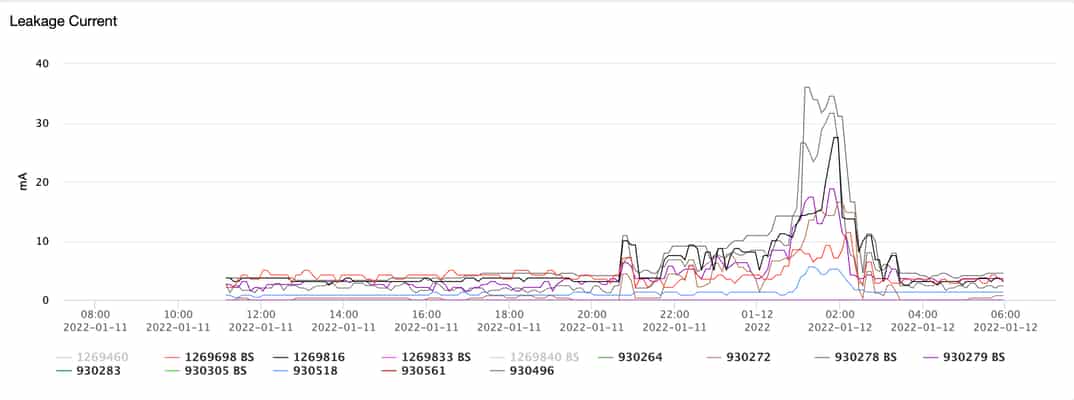

Algorithms and analytics are needed to convert interesting leakage current magnitude data into actionable information. EPRI developed algorithms that can generate alerts when there is a need to wash insulators and alarms when there is a high flashover risk, through multi-year tests at the Lenox, MA laboratory with artificially contaminated insulators under natural wetting conditions. The developed algorithms were implemented at 161kV, 230kV, and 345kV, but can be extended to higher and lower system voltages.

We have also developed analytics tools to evaluate leakage currents over a year or more. These tools are useful when evaluating the degradation of coatings and composite insulators.

Low-Cost Mechanical Attachment

Our Leakage Current RF Monitors are easy to install and do not require the addition of standoff insulators or replacement of individual discs. They are installed at the grounded (earthed) end of existing insulators or insulator strings, which keeps the installation costs low.

Our Leakage Current RF Monitors are designed to attach to three types of insulators:

- Post-type or long rod porcelain insulators – Utilize a metal band as current pickup

- Composite insulators – Utilize a metal collar as current pickup

- Glass or porcelain discs - Clamp-on design fits on ground end of existing discs

Data integration and visualization

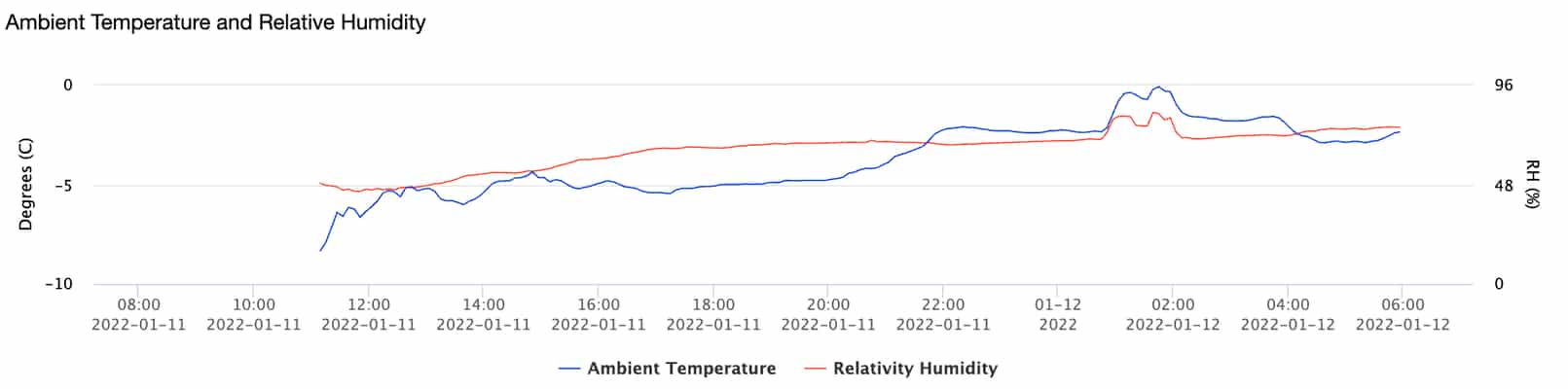

Data from each RF Monitor is transmitted wirelessly to a base station (which also measures local temperature, humidity, rainfall, wind speed and direction) using frequencies in the 2.4GHz open band. A single base station can aggregate data, store, and transmit data from up to 48 RF monitors. When working with EPRI, a cell phone modem transmits the information from the base station to our central servers.

EPRI’s secure servers store real-time and historical data, as well as environmental parameters, for utility stakeholders to view as needed. Algorithms will alert and alarm stakeholders when contaminated insulators require attention.