EPRI Insulator Leakage Current Monitor: long rod, disc and composite: Use case

The problem:

The power utility aimed to address safety and maintenance issues caused by insulator contamination from marine salt, road salt, and industrial pollutants. These contaminants can lead to equipment damage and outages, posing significant risks to the reliability and safety of the electrical grid.

RF monitoring approach:

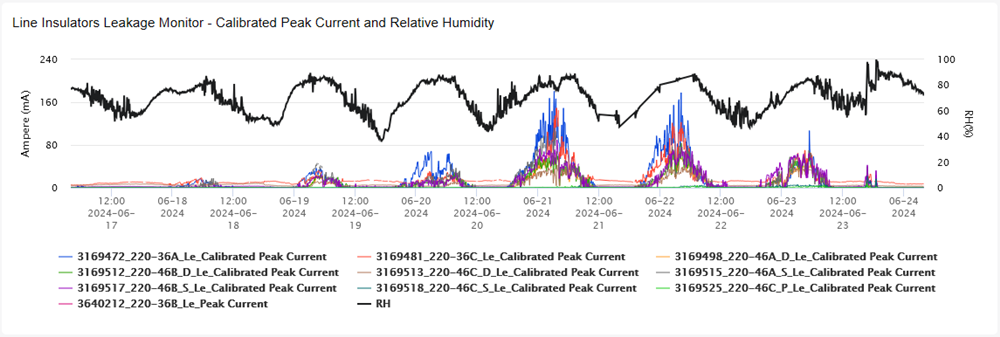

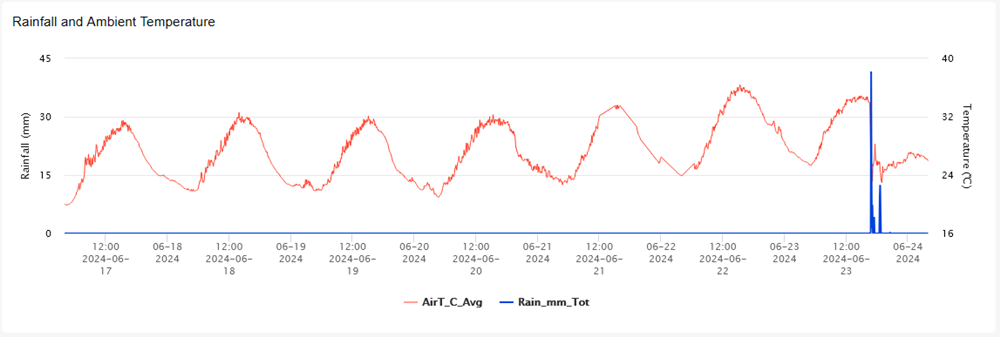

EPRI implemented RF monitoring systems by installing leakage current monitors on various types of insulators, including long rod, composite, substation post, glass, and porcelain disc insulators. These self-contained units wirelessly transmit data to a base station, which aggregates and sends the information to servers. The data is then visualized on a website, with automatic alerts sent to stakeholders.

Lessons learnt:

The research demonstrated that RF monitoring is effective for continuous, real-time detection of insulator contamination. It highlighted the importance of accurate data collection and analysis in making informed maintenance decisions. Additionally, the project underscored the need for continuous improvement of alarm algorithms to further reduce false alerts and enhance the accuracy of maintenance recommendations.

Status:

Currently, RF monitoring systems are operational at over 30 sites, with ongoing efforts to expand their use. CenterPoint Energy, for example, has successfully used these monitors to improve maintenance efficiency and plans to extend the technology to more substations. EPRI continues to refine its RF monitors, leveraging over a decade of expertise to enhance their durability and functionality, ensuring they remain a valuable tool for energy companies.